Improvement of Rubber Industry Quality with High-Quality Heating Elements from United Heater

The rubber industry plays a crucial role in various sectors, from automotive to manufacturing. In the effort to enhance the quality of rubber products and achieve better production efficiency, heating becomes a key factor that cannot be overlooked.

What's the connection between the rubber industry and heating elements? Let's discuss how heating elements significantly impact the rubber industry and what heating elements are utilized.

In the process of manufacturing rubber products, the heating process is a vital step that influences the quality and physical properties of the rubber material. Some important processes that require heating include rubber material mixing, vulcanization, curing, and molding. Proper and consistent heating is key to achieving desired physical properties in rubber products, such as strength, elasticity, and resistance to extreme temperatures.

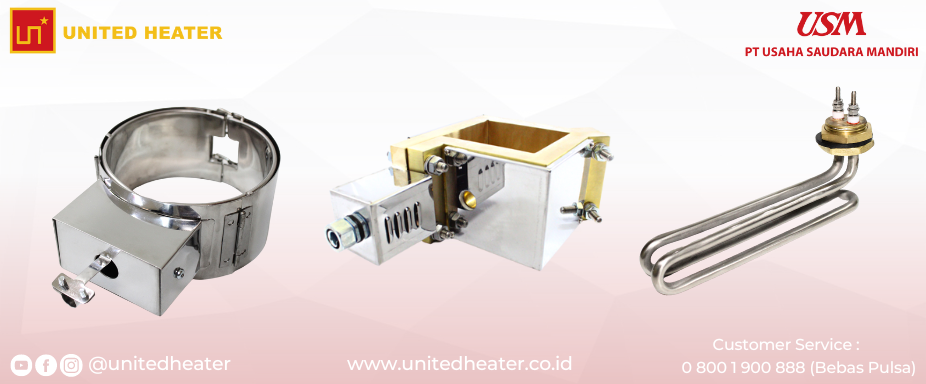

The rubber industry utilizes various types of heating elements to achieve consistent and optimal heating. Some common types of heating elements used in the rubber industry include:

1. Cast In Heater

Cast In Heaters can be used for heating in rubber casting, vulcanization or curing processes, as well as rubber drying. With advantages like precise heating, efficient energy usage, and flexible design, Cast In Heaters can produce high-quality rubber products.

United Heater produces several types of Cast In Heaters, including Cast Iron, Brass, and Aluminum. The maximum temperatures for Cast Iron, Brass, and Aluminum are 500 degrees Celsius, 400 degrees Celsius, and 350 degrees Celsius respectively.

2. Band Heater

Band heaters are a suitable and beneficial type of heating element for various applications in the rubber industry. They can be used for heating cylinders and tubes used in rubber production, such as extrusion machines or molding machines.

United Heater's band heaters can operate at a maximum temperature of 250 degrees Celsius for standard types and 350 degrees Celsius for special types.

3. Tubular Heater

In some cases, tubular heaters can be useful heating elements for heating the surface of rubber to shape, forge, or wrap rubber products. Tubular heaters provide concentrated heat to the rubber surface, facilitating further processing.

4. Cartridge Heater

Cartridge heaters are often used in rubber molds. They are installed into holes in the mold and provide precise heat for the vulcanization or curing process.

With precise and stable heating, cartridge heaters ensure optimal durability and elasticity of rubber products. United Heater produces high-quality cartridge heaters that can reach a maximum temperature of 650 degrees Celsius.

As a company specializing in heating elements, United Heater recognizes the crucial role of quality heating in the rubber industry. With high-quality products and reliable technical support, United Heater offers the right heating solutions to meet the unique needs of every rubber industry application.

Consult your needs immediately for free with our team at 0 800 1 900 888 (toll-free). Get the right heating element solution for your industrial application needs. Don't forget to visit our website at unitedheater.co.id and United Heater social media at @unitedheater.