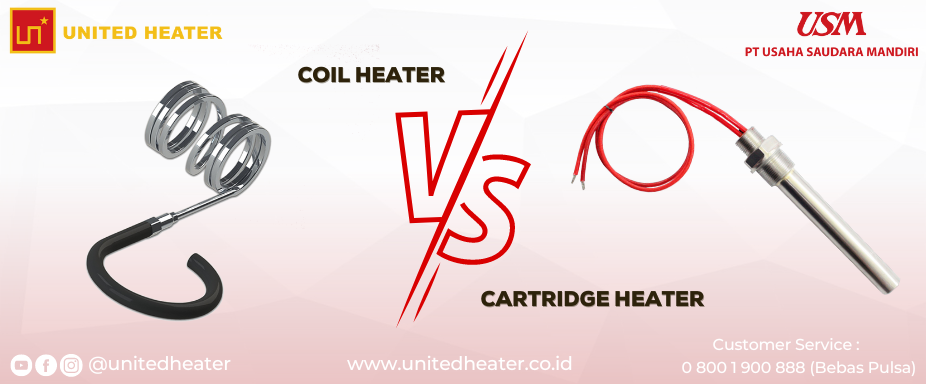

Coil Heater vs Cartridge Heater: Which is More Suitable for Your Application?

In the world of industrial heating, there are two commonly used heater technologies in various applications: Coil Heater and Cartridge Heater. However, you might wonder, which one is more suitable for your needs? Let's explore further about these two types of heaters and find the right solution for you!

Coil Heater is a heating element designed in a coiled shape, providing flexibility to adapt to various shapes and sizes of heating surfaces. Its ability to generate rapid and uniform heat makes it a popular choice for applications such as mold heating, plastic injection, and various industrial equipment requiring precise heating. Coil Heater can reach a maximum temperature of up to 400 degrees Celsius.

On the other hand, Cartridge Heater is a compact and efficient cylindrical heating element. With excellent thermal insulation materials, Cartridge Heater can maintain consistent and stable temperatures. This makes it an ideal choice for applications that require precise and consistent heating, such as die-casting molds, liquid heating, and welding processes. Cartridge Heater can reach a maximum temperature of 650 degrees Celsius.

The selection between Coil Heater and Cartridge Heater depends on various factors, including the specific heating needs of your application, environmental conditions, and desired temperature requirements.

Consult your needs immediately for free with our team at 0 800 1 900 888 (toll-free). Get the right heating element solution for your industrial application needs. Don't forget to visit our website at unitedheater.co.id and United Heater social media at @unitedheater.