Advantages and Uses of Cast In Heater

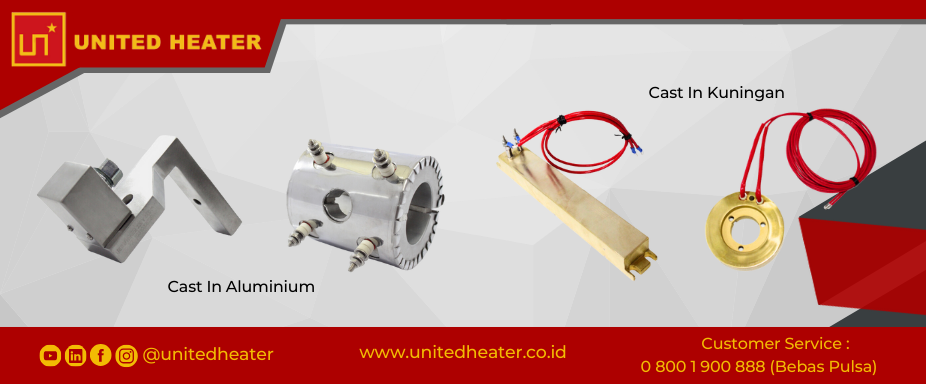

Cast In Heater is one of the heating elements designed from Tubular heater and is often used in various types of industries because it has several advantages, namely more heavy duty, resistant to corrosion, and resistant to impact or vibration of the industrial environment. Cast In Heater can operate with temperatures that are adjusted to the type of material used, namely:

- Cast In Iron: 500 ℃

- Cast In Brass: 400 ℃

- Cast In Aluminum: 350 ℃

Uses of Cast In Heater:

- Heats the mold in which the material or rubber is melted and molded.

- Melts the metal.

- Used in the heating process of tanks, pipes, or other equipment in chemical processes.

- Maintain the temperature of oil or other liquids in storage tanks in the oil and gas industry.

- Used for the manufacturing process of pharmaceutical products.

- Controlling temperature to be consistent in temperature control systems.

- As a tool for equipment testing or laboratory research for specific heating processes in experiments.

Cast In Heater is safely designed according to the efficiency in its application. Since Cast In Heater is often used to melt materials, the installation process of Cast In Heater must be correct to minimize the risk of damage or failure in the heating process.

Consult your needs immediately for free with our team at 0 800 1 900 888 (toll-free). Get the right heating element solution for your industrial application needs. Don't forget to visit our website at unitedheater.co.id and United Heater social media at @unitedheater.