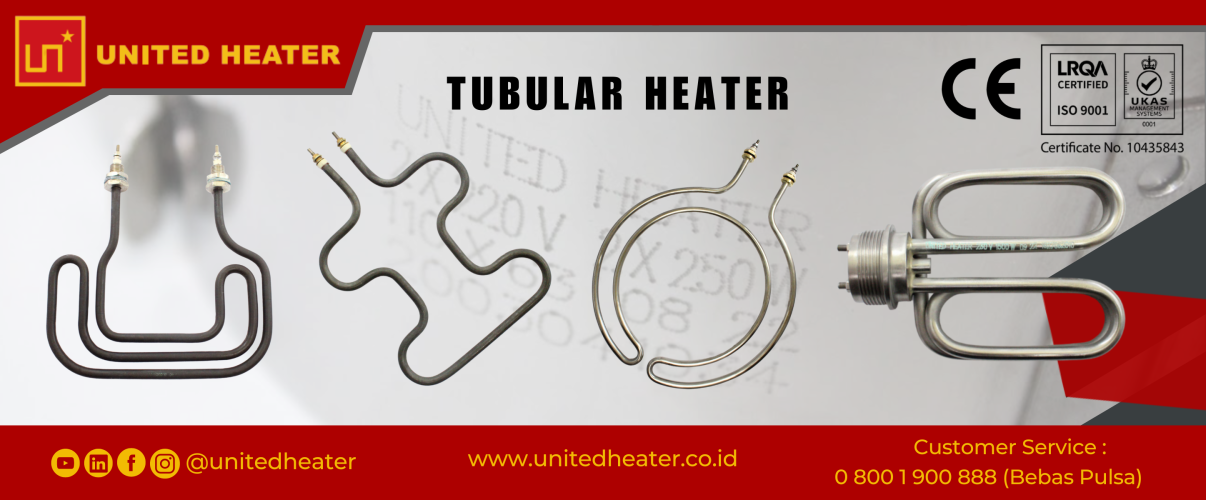

Advantages, Disadvantages, and Application of Tubular Heater

Tubular heater is the most versatile electric heating element and is widely used for industrial, commercial, and pharmaceutical applications. Tubular heaters are used for indirect heat exchange, the heating medium can be gas or liquid, such as steam or oil, and can be used for conduction, convection, heat-emitting heating depending on the placement and usage.

Advantages of Tubular Heater:

- Efficient in heat transfer. The high level of watt density and the solid outer layer cause optimal heat transfer from the coil to the heated medium (air, liquid, or solid).

- Strong and durable durability. Tubular heaters have a strong structure that is resistant to physical stress, vibration, thermal shock, and corrosion. It is also low-maintenance and has a long service life.

- Customizable and adaptive. These heaters can be customized to different shapes and sizes, and are resistant to various chemicals, temperatures, and pressures.

- Compatible. The sheath installation and removal process is made easy with a variety of connection options, such as threaded, flanges, brackets, and clamps. This heater can also be connected to thermostats, controllers, or thermal power and temperature control sensors.

Disadvantages of Tubular Heater:

- High thermal risk. The high temperature generated by the tubular heater may exceed the safe limit of the heating medium or the surrounding environment resulting in damage to the heated material or equipment.

- Limited bending range. Tubular heater has a flex limit by its diameter and material layer to avoid damage to the coil. Tubular heater must be bent properly to avoid excessive pressure and tension.

Applications of Tubular Heater:

- Clamp on platens

- Dies

- Mold

- Sealing tools

- Food heating

- Air ducting

- Ovens and furnaces

- Drying

- Load bank

- Discharge resistor

- Plastic sheet bending equipment

- Paint and enamel baking equipment

- Welding preheat equipment

- Curing

- Steam

- Textile and chemical dryers

Consult your needs immediately for free with our team at 0 800 1 900 888 (toll-free). Get the right heating element solution for your industrial application needs. Don't forget to visit our website at unitedheater.co.id and United Heater social media at @unitedheater.